Seam welding is the process of connecting two parts by welding them together. It is a standard process in ceilings, walls, and other structures. The primary purpose of seam welding is to connect two parts that are too heavy or too hard to support each other. The result is that the part is light and easy to move.

The main benefit of seams welding is creating a connection between two parts with minimal effort. When you perform seamless welds, you can do it under direct sunlight without any heat. This means that you can achieve better results than with other seam welding processes because the welded part is never joined together until after the process has been completed. The part is divided into two parts that are then combined by welding them together.

To perform seamless welds, you need a weaver’s spanner, found at most metal fabricators’ stores. The weaver’s spanner is a long, thin, and sturdy tool that can be used instead of a straight edge when connecting the parts.

Types of Seam Welding

There are many types of seam welding:

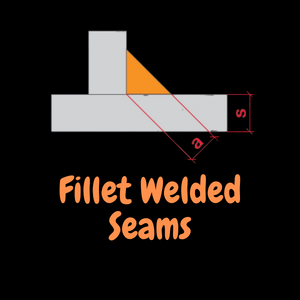

Fillet Welded Seams

Welded corners, laps, and tee joints are referred to by the term “fillet welded seams.”. About 75% of all welding joints are made with this type of seam. It is easy to weld piping systems with this joint type since there is no need to prepare the edge. The cost of butt welding is higher than fillet welding. The most common use of flattened welds is to connect pipe to socket joints in piping systems.

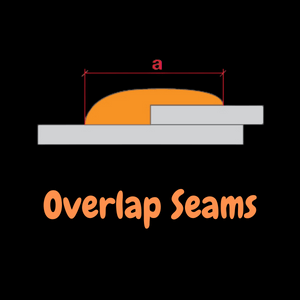

Overlap Seams

As a result of one seam overlapping another, it forms a continuously welded seam that is leak-proof. It is also neat and well-finished. Ideal for welding floors and roofs.

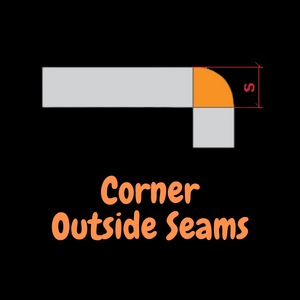

Corner Outside Seams

The corner welding joint on the outer edge of the piece is one of the most common types of weld in the sheet metal industry. L-shaped joinery is created when two metal parts are connected at right angles. Boxes, box frames, and similar fabrications are often made with these types of connectors.

V-Seams

A V-shaped angle is usually achieved by either beveling the workpieces or orientating them at an appropriate angle.

X-Seams

An X seam or double V join is also known as a double-V seam. A buttweld consists of two V-seams that are welded onto both sides of the component to be joined.

The single butt weld offers many of the benefits of the bevel joint, but instead of having one side beveled, both sides have beveled edges. A double-V joint is used where welding can be done from both sides of the workpiece in thick metals. Having two V-joints that are narrower, a double-V joint needs less filler when welding thicker metals than a single-V joint.

A double-V joint provides additional warping compensation. A V-joint often warps in only one direction when stressed, but a double-V joint has welded seams on both sides, which relieve and create opposing stresses that straighten the material.

Lap Seam Welding

Lap seaming is the process of welding two pieces of metal together. Building ceilings, walls, and other structures rely on this process. An ideal lap weld would join two heavy or difficult-to-support parts that would otherwise be disconnected. This creates a lighter, easier-to-move part.

Mash Seam Welding

When two parts are welded together, a seam is formed between them. Welding seams are a method used primarily to join heavy or hard pieces that cannot be supported otherwise. Because it is relatively light and flexible, the piece can be easily moved.

The use of this method is a great way to connect two parts that are too heavy or too hard to support each other. This gives you the ability to have a claim that is lightweight and easily movable.

Butt Seam Welding

A shoulder seam is a seam that is formed by sewing two parts together by pressing them together with a pressure-sewn rivet. Having the sewn pins makes it easy to work with and move. In ceilings, walls, and other structures, this can be found as a standard practice. A butt seam is welded to connect two parts that can’t support each other due to their weight or hardness. A light and easy-to-move part is the result. With these eight welding seams, we hope we’ve given a better picture of what welding seams are and how to form them.

It’s been years since I got into welding as a side hustle. It’s been so long since Doing All kinds of welds for business and pleasure as this is my hobby. Being in this field I have learned from hands-on-experience also came to know what gears work and what doesn’t. The Tig Welder is my own platform where I use to share my experience.

Leave a Reply