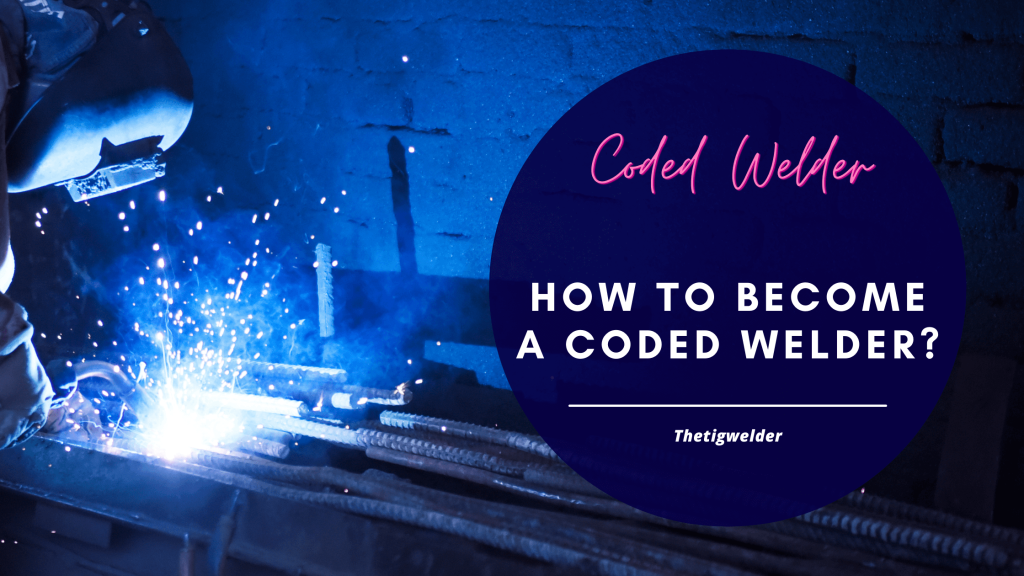

A coded welder is someone who has completed a Welder Approval Test in a specific welding configuration. As a coded welder, you will possess the skills required to work in some of the most highly regulated sectors. This certification allows work on safety-critical applications such as pressure vessels and pressure pipework.

In the UK, welder approval codes are to BS EN ISO standards. The USA uses the ASME IX standard.

Each method is specific to a particular job at hand, some codes are more general, and some are very specific. The more particular methods need individual parameters allocated via a weld test inspector. You can offer to test to that specification. A welding specification requires testing to that specification. The welder will offer a welding sample that closely resembles the position possible. This will allow you to produce a weld following written instructions.

This means that it will satisfy you with knowing that you are doing what is necessary for the correct result, which is often difficult to achieve, while still trying to improve life by doing what is difficult.

How to Become A Coded Welder?

It’s a great choice – the welding industry is booming, and there are plenty of opportunities for skilled welders. But before you can start welding your way to the top, you need to obtain your Welder Approval Test certification. Welders may be coded to meet job requirements. Something may also code them to expand their Skillset and apply for more jobs.

Becoming a coded welder requires anywhere from a few classes to several years, culminating in a test for the code.

Employers may have different requirements for welders, but high school diplomas or GEDs are required. Depending on the position, additional training may be necessary. The requirements for welding degrees vary depending on the school.

Becoming an apprentice can be an effective way to get on-the-job experience in medicine. Welders can choose their career path based on the type of welding they wish to do, the type of company they want to work for, and the type of work they wish to do.

How to Get Coding Welder Approval

The approval test is not a simple task. To complete the test, you need to have the skills required to work with pressure vessels and pressure pipework. You also need to have the experience and skills to weld these products. After taking the approved tests, you will start working with pressure vessels and pressure pipework.

The challenge with this code is that it is specific to the job at hand. There are no templates or instructions related to the coded welder position. You will need to produce a weld following written instructions to complete the code.

How to Produce a Coded Weld

To produce a coded weld, you will need:

- Welding experience

- Welding skills

- Welding test code

- Welding test method

- Welding test schedule

How to Produce Square Welds

There are specific skills, and knowledge needed for welding depending on the job. There are different codes for different jobs; some are more general, while others are more specific. Weld test inspectors need to allocate parameters to more particular methods. To create square welds, you need to follow written instructions as well as have the skills and knowledge required.

How to Produce Cascade Welds

Cascade welds are a type of weld that results from the connection of two different metals.

The result is a physical connection between two metal types that have been separated. This new material becomes integrated with the content of the welder and begins to fill and bulge from the weld. The efficiency of the welders’ skills is increased because of this smooth transition.

Cascade welds are not as standard but are worth mentioning because they are a better way to connect two different metals. The advantage of these welding configurations is that they are more reliable and effective because they don’t require any additional technical skills or knowledge.

Production Tips for Codes and Welding Organisations

Welding is an important field, and with good welder approval codes, the skills are required to work in some of the most safety-critical applications. You will work on a range of production-based jobs, so you need to handle complex tasks.

Get welder approval codes from a weld test inspector. This will allow production welds that mirror the position as closely as possible.

How Are Qualifications Tracked?

For welding codes, there are a variety of methods for tracking qualifications. Three of the most common are:

- WPS (Welding Procedure Specification). A weld procedure document specifies the approved procedure for a specific weld type. There are specific materials that are to be welded.

- QPR (Procedure Qualification Record). This record documents the data used in developing the WPS.

- WPQ (Welder Performance Qualification). The welder’s qualification certification is the official record that states what they have done and what their qualifications are.

What Is 6g Coded Welding?

6G coded welding refers to a welding certification test where the welder is required to weld a pipe joint in the 6G position, which is at a 45-degree angle. This test is considered one of the most challenging as it requires the welder to have advanced skills in various welding techniques and the ability to work in a difficult position. Passing the 6G certification test is highly regarded in the welding industry and demonstrates a welder’s proficiency and expertise.

The Difference Between Coded Welders And Certified Welders?

Coded welders are certified welders who have passed additional tests to obtain specific welding codes or certifications, such as ASME or AWS, that are required for welding certain materials or structures in specific industries. Certified welders, on the other hand, have passed standard welding tests that demonstrate their general welding skills and knowledge. In short, all coded welders are certified welders, but not all certified welders are coded welders.

It’s been years since I got into welding as a side hustle. It’s been so long since Doing All kinds of welds for business and pleasure as this is my hobby. Being in this field I have learned from hands-on-experience also came to know what gears work and what doesn’t. The Tig Welder is my own platform where I use to share my experience.

Leave a Reply